TILTEX

TILTEX® is a Cement Geocomposite for erosion control and mechanical protection of waterproofing geomembranes.

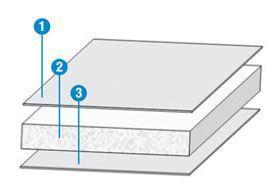

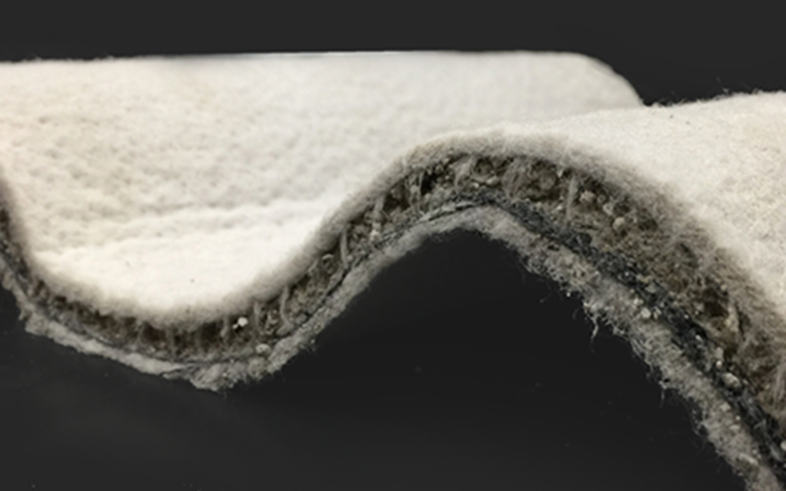

Composed of a mixture of cement and sand, TILTEX® is compressed between two layers of geotextile which allow it to be flexible and adaptable to any type of surface during installation.

The composite is stable thanks to the mechanical punching which allows the union between the fibers of both geotextiles: in this way the base of the cementitious component is strengthened, giving cohesion to the whole.

1- Geotextil in polypropilen

2- Cement-sand mixture

3- Geotextil in polypropilen

TILTEX® PLUS

It is also possible to couple a 0.2 mm thick polypropylene or polyethylene film to Tiltex® to increase its waterproofing properties and installation for specific uses.

ADVANTAGES

Quick use

Supplied in rolls of different weights and sizes, Tiltex® does not need formwork or concrete mixers for its application, it just needs water!

Safe

The product contains the adequate amount of cement for the intended use. The cement remains confined between the two external layers of geotextile and there is no loss of thickness, regardless of the type of application.

Durable

Thanks to its cementitious component, Tiltex® is highly resistant to static drilling, erosion and UV rays. The fibers that cross it, guarantee the good resistance of the product to cracking.

Environmentally friendly

The use of Tiltex® allows you to limit the thickness of the concrete used for normal protective castings on site. Furthermore, it prevents product waste that occurs with the use of shotcrete and can be used to restore the surfaces of existing concrete solutions without foreseeing demolition works.

Easily adapts to any surface

Because it is flexible before hydration, Tiltex® conforms to all shapes - vertical, curved, etc. - and types of surfaces. Furthermore, it can be easily cut to size to fit the needs and dimensions of the application site.

TILTEX IN 4 STEPS

1- UNWINDING

Large dimensions Tiltex® rolls must be unrolled with suitable lifting and moving means such as pulleys/moving beams.

2- SIDE FIXING

It is recommended to fix all Tiltex rolls with Tiltex® nails P1, P2, P3 or P4, depending on the characteristics of the application surface.

3- ABUNDANT IRRIGATION

Irrigation should be done by spraying plenty of water without pressure. The quantities required depend on the thickness of the product.

4- FINISHED INSTALLATION

After 24-48 hours (depending on environmental conditions) the product becomes a rigid concrete slab and is ready for use.

APPLICATIONS

Ditches, canals and trenches.

Temporary or permanent protection.

Mechanical protection of waterproofing membranes.

Erosion control (railway or road ballasts, parapet excavations and water basins banks).

Packaging

TILTEX® is available in different thicknesses (7-9-10 e 12 mm) and weights of 7, 9, 10 e 12 kg/m². Rolls are available in three different dimensions:

- 5 m x 20 m

- 2,5 m x 20 m

- 1 m x 5 m